INTRODUCTION:

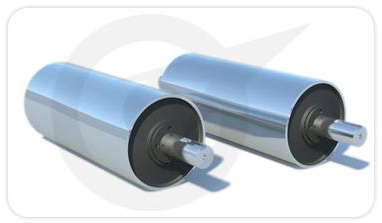

STAR TRACE's Magnetic Head Pulley provides effective way to remove ferrous contaminant from powdery, schistose and granulate material, like ore, coal, waste, sand and etc. Magnetic head Pulley is composed of 360 degree magnetic core protected by rotatable stainless steel cover and a axis of rotation. In practice, surface of Pulley will be wrapped by belt, so as material flow over it. Ferrous contaminant will be attracted at belt and be conveyed out of material. In many applications, it’s possible to replace an existing head pulley with a permanent magnetic head pulley, on a size-for- size basis. A wide range of diameters, widths, and shaft sizes are available.

DESIGN ADVANTAGE:

STAR TRACE Magnetic head pulleys are built using our exclusive flux control magnetic circuit. This design ensures continuous magnetism around the entire circumference of the pulley-no dead spots. For less critical applications, a conventional magnetic circuit design is also offered.

TYPES OF STRENGTH:

Light duty

For general use with burden depths up to 50mm. Belt speeds to 1.8m/s. Good for secondary Clean up of misc. tramp iron and fines.

Medium Duty

For general use with burden depths up to 75mm. Belt speeds to 2m/s. Used in Construction & Demolition and Material Recovery Facility.

DESIGN ADVANTAGE:

STAR TRACE Magnetic head pulleys are built using our exclusive flux control magnetic circuit. This design ensures continuous magnetism around the entire circumference of the pulley-no dead spots. For less critical applications, a conventional magnetic circuit design is also offered.

TYPES OF STRENGTH:

Light duty

For general use with burden depths up to 50mm. Belt speeds to 1.8m/s. Good for secondary Clean up of misc. tramp iron and fines.

Medium Duty

For general use with burden depths up to 75mm. Belt speeds to 2m/s. Used in Construction & Demolition and Material Recovery Facility.

Website:http://www.magneticpulley.com

Video:

Video:

No comments:

Post a Comment

Note: only a member of this blog may post a comment.