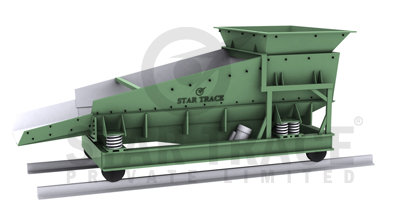

The metallic components like scrap, bales, pig iron and foundry retains are stored in the hopper. The hopper shape is specially designed to enable bulky and irregular scrap pieces to be extracted without problem. Vibrating furnace charger is effective solutions to problems such as high labor cost, hazards operators faced in foundries, melting shops etc. Such a kind of automation allows foundry men to work at a safe distance thus preventing injuries arising out of molten metal splash. It also facilitates in rapid and quick charging of the furnace thereby allowing maximum utilization of the furnace, in addition to this, the damage to furnace lining is avoided which normally occurs in manual charging of the furnaces.

Vibratory

Furnace Charger consists of a vibrating feeder mounted on a moving

trolley with a storage hopper mounted above the feeder. Our company make

vibratory furnace chargers basically comprise of the following parts.

Vibrating Feeder suitable for delivering required capacity. Storage

hopper of required capacity. Moving carriage with driving arrangement.

Control panel for operating the system. Cable reeling Drum / Cable Drag

Chain.

The charging car on the vibrating furnace charger

comprises a discharge chute with vibratory feeder for the metallic

components and is hopper all mounted on the traveling framework with

drive gear. The discharge snout is inclined and formed of a rounded

trough to bring about a good charge distribution and enable irregular or

bulky pieces of scrap or returns to be discharged. The feeder is driven

by unbalanced motors. The vibration frequency can be altered by an A.

C. Inverter, thereby regulating the feed velocity and also influencing

the noise emission. The batch hopper as well as the charging feeder is

built in sandwich construction which reduces the noise generated by

contact between the charge materials and the hopper walls or feeder

deck. However, this does not eliminate the noise produced by contact

between the charge pieces themselves.

Vibratory Furnace Charger Operating Principle

The required amount of

scrap metal is loaded into the storage hopper at the loading point. The

trolley then carries the vibrating feeder along with the storage hopper

to the furnace charging point. Here, the vibrating feeder is energized

and the material is effectively discharged into the furnace as per the

required capacity. As the metal is melted down, fresh batch of metal can

be fed into the furnace thereby keeping the furnace full. The capacity

of the vibrating feeder can be varied by varying the amplitude of

variations. The amplitude of vibrations can be varied by adjusting the

position of centrifugal weights or by using a variable frequency drive

(optional). A control panel specially designed to suit individual client

requirement depending on the sequence of operations required is

provided.

Advantages for Using A Vibrating Furnace Charger

- Very fast as compared to manual charging of furnace thereby enabling optimum use of the melting system.

- Extremely controlled charging of material into the furnace.

- Prevents damage to the furnace lining since the material is properly guided into the furnace so as to avoid the material from hitting the furnace walls.

- No direct exposure of manpower to the furnace thereby preventing dangerous accidents due to metal splash (since the operator can carry out the operations at a very safe distance.

- Minimum heat loss of the furnace since the charging process can be maintained continuously at the required rate.

video:

No comments:

Post a Comment

Note: only a member of this blog may post a comment.